INDUSTRIAL WASTEWATER TREATMENT

THE CHALLENGE

Wastewater treatment is one of the most significant and impacting challenges (environmental, costs, regulatory constraints) of any industrial factory. A simple, efficient, and cost-effective solution is of great need.

Wastewater treatment is one of the most significant and impacting challenges (environmental, costs, regulatory constraints) of any industrial factory. A simple, efficient, and cost-effective solution is of great need.

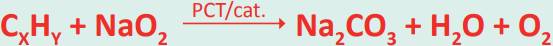

THE TECHNOLOGY

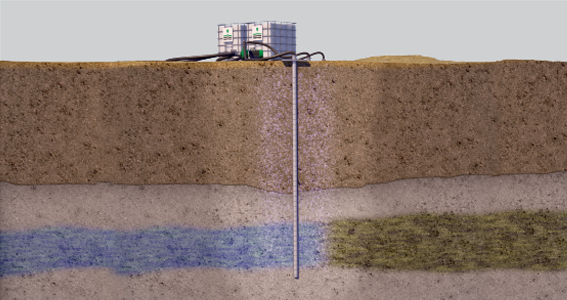

WWO -wastewater oxidation is an in-situ, chemical oxidation process based on the synthetic generation and stabilization of highly concentrated superoxide radical in an aqueous environment. The process is based on a new synthetic way of producing and stabilizing superoxide radical in an aqueous environment.

WWO -wastewater oxidation is an in-situ, chemical oxidation process based on the synthetic generation and stabilization of highly concentrated superoxide radical in an aqueous environment. The process is based on a new synthetic way of producing and stabilizing superoxide radical in an aqueous environment.

VALUE PROPOSITION

u

Alpha Cleantec has developed a new and rapid solution (technology and machinery) able to decontaminate a wide range of organic pollutants (such as BTEX, TPH, PAH, CHC, PCB, crude oil, and drug leftovers) with contaminations of up to 100,000 ppm providing high conversion rates of > 90 %.

u

The technology can be applied as an on-site treatment process or with existing equipment for in-situ treatment.

u

The methodology can be applied as a standalone process or as part of existing wastewater treatment processes.

u

The technology can be integrated in the manufacturing process or operated as a stand-alone turnkey solution.

BENEFITS OF OUR SOLUTION

| Granted patents | |

| Elimination of contaminants in minutes to hours | |

| Decontamination without toxic by-products | |

| Insignificant CO2 footprint | |

| Treatment of a wide range of contaminants (BTEX, PAH, CHC, PCB,) up to 100,000 ppm with high conversion (> 90 %) |

| Very low electricity requirement | |

| Safe for users and environment | |

| Adaptable to existing equipment and process | |

| Cost-effective | |

| Treatment procedures do not restrain the continuous and safe work on site |

Some of our partners